Environmental aspects of coil coating

BackEnvironmental aspects of the coil coating process

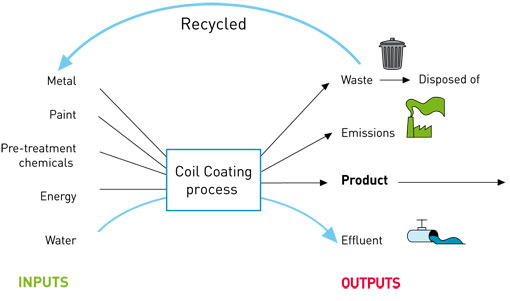

Coil coating is a highly industrialised and controlled process with a number of inputs and outputs. Inputs to the process include metal substrates, paint, pre-treatment chemicals, water and of course energy. Outputs include solid waste, effluent and vapour emissions in addition to the prepainted product itself.

Prepainted metal production has developed over the last 50 years into a very clean process. Most installations are of a size which require a licence to operate under various European regulations; the coil coating process is carried out under very tightly controlled conditions. Unlike many smaller post-coating operations, this provides an assured level of environmental compliance to both national and European regulations.

The environmental impacts of the coil coating process include:

|

Read more

| Introduction to the coil coating process |