About

Prepainted Metal

The coil coating process which is used to produce prepainted metal is continually evolving to produce better products, higher quality, faster and with lower environmental impact.

Benefits of Coil Coating

200kT

100

About Coil Coating

The coil coating process which is used to produce prepainted metal is continually evolving to produce better products, higher quality, faster and with lower environmental impact. Some of the major innovations in recent years have been:

The basic technique of applying paint by roller coating is at the heart of prepainted metal and continual innovation is used to make this faster, more consistent and more efficient

The adoption firstly of reverse-cascade rinsing and then of no-rinse pre-treatment on many coil coating lines has dramatically reduced water usage in the initial stages of the process

The most energy-intensive part of the coil coating process has seen major development to provide more efficient ovens, able of curing paint in seconds, using both traditional gas-fired techniques, but also innovative induction, IR/NIR, UV/EB curing techniques

The coil coating process allows for very efficient collection of VOCs from the solvents used in paints and the latest oxidisers ensure that over 99% of these are destroyed without polluting the atmosphere.

Testing Prepainted Metals

|

Prepainted metals are widely used in many different applications and environments e.g. exterior and interior buildings, domestic appliances, furniture, etc. These products are tested in accordance with the requirements of the product specification and particular market application. Over the years, a number of test methods have been developed to ensure that the material is fit for purpose for the desired application. The relevant European standards (EN) are based on test methods developed by ECCA and are available from all European National Standardisation Institutes. Some EN standards specify test methods that deal with parameters such as the thickness of paint layers (EN 13523-1) or the retention of gloss properties (EN 13523-2). Other EN standards deal with the mechanical properties such as bend tests (EN 13523-7) or pencil hardness test (EN 13523-4). Another important test relates to the chalking of the prepainted surface (EN 13523-14). In addition to the European Standards, some prepainted metal users e.g. appliance manufacturers, have established their own specific test methods dependent on the final use of the material. For example, some washing machines manufacturers are interested in the resistance of the painted surface against alkaline solutions. Refrigerators are tested for resistance against foodstuffs and beverages with aggressive properties e.g. ketchup or vinegar. |

ECCA markets and stats

The prepainted metal market is a key player in global industries, covering 1,407 million square meters in 2024 alone. Widely used in construction, automotive, and consumer goods, prepainted metals offer durability and aesthetic flexibility. As demand for sustainable materials grows, the market continues to expand, meeting the evolving needs of modern industries.

- ~85% of the market

- 188kT of Paint applied in 2024

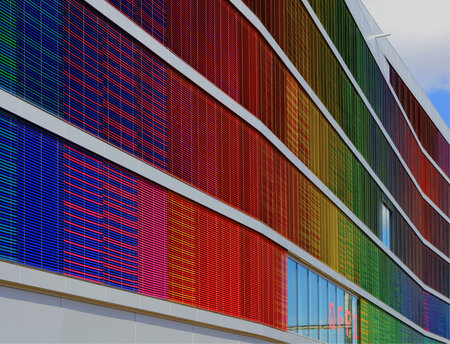

Get inspired

Contact us

Keep in touch